Common Industrial Accidents

Common Industrial Accidents and How to Avoid Them

Many industrial accidents happen due to improper lifting and storage of products and machinery. These hazards can cause serious injuries or even death. In this article, we’ll talk about some of the most common types of industrial accidents and how to avoid them. If you’re working in an industrial setting, you should always wear proper safety gear to avoid these types of injuries.

Defective machinery

Defective machinery can lead to a number of different types of injuries, including electrocution, facial disfigurement, and even death. As a result, a victim of an industrial accident may be entitled to compensation from the responsible party. Los Angeles Personal Injury Attorney In some cases, the manufacturer of the machinery may also be held liable.

The Bureau of Labor Statistics has estimated that there are 2.8 million workplace injuries each year. Of these, many workplace injuries are the result of dangerous machinery. In fact, the Occupational Safety and Health Administration (OSHA) lists unsafe machinery as one of the top workplace safety violations. Although most employers adhere to OSHA regulations, a few still disregard worker safety.

Toxic chemicals

Toxic chemicals are present in workplaces throughout industries, and they can cause serious health issues and even death. They can enter the body through skin contact and air. These chemicals are subject to regulations in order to protect the health of workers. Violations of these regulations can result in fines and work-related accidents.

In the United States, large amounts of toxic industrial chemicals are produced, stored, and transported. Terrorists can obtain these chemicals and cause significant harm to innocent people. Some toxic industrial chemicals, particularly those released through aerosolization, are highly persistent in the environment. The length of time they remain in the environment is dependent on several factors, including chemical stability, the method of release, and the quantity released.

Improper lifting

Improper lifting is one of the most common causes of workplace injuries. This is because lifting heavy objects without proper handholds puts undue stress on the body. It can also lead to lower bending, which increases the risk of dropping the load. To prevent injury, employees should always be provided with back braces and proper footwear before they begin lifting objects. It is also vital to provide employees with ample space to do their lifting duties.

Before lifting any object, you should carefully examine the object to ensure it is not hazardous. You should also evaluate the travel path and consider the load’s weight limit. For example, if the load is very heavy, ask for assistance from someone else. It is also helpful to divide the load into smaller parts. You should follow proper lifting principles, such as placing your feet shoulder-width apart, keeping your back vertical, and not twisting.

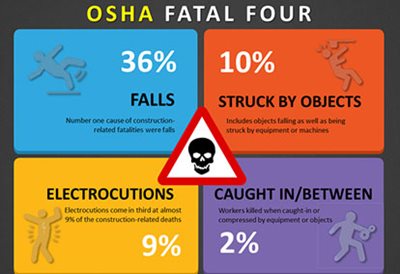

Slips and falls

Slips and falls are among the most common accidents in the workplace, accounting for one out of four workplace injuries. These accidents cause countless missed work days, and 15% of all accidents result in death. However, many of these accidents are preventable. One of the most common causes is human error, including improper housekeeping and improper maintenance of ladders and stairs. In addition, uneven or wet surfaces are the leading cause of slips and falls, accounting for about 55% of all cases. Other common causes include cluttered floors, loose floorboards, and recently mopped floors.

A recent report from the Health and Safety Executive (HSE) outlines the most common types of workplace accidents and their consequences. Slips and falls account for nearly a third of all non-fatal accidents, while falls from height account for an even higher proportion. Slips and falls from a height can occur from scaffolding, ladders, or even a tree. These injuries can occur anywhere, and they can cause devastating, debilitating injuries for workers. Sadly, this can result in a significant cost.

Lack of training

According to the Health & Safety Executive (HSE), in Great Britain, there will be 142 work-related deaths between 2020 and 2021. This statistic highlights the need for employers and employees to follow stringent health and safety guidelines. Occupational safety and health is particularly important in industrial settings, as these places are often high-pressure and high-risk environments.

Many industrial accidents can be prevented by providing adequate training to workers. Training is an essential component of occupational safety and health (OSH). Lack of safety training has been proven to increase risk of injury and illness. In addition to training, workers should follow guidelines for workplace safety. For example, workers should make sure that the doors are closed properly and that slippery substances are swept away quickly. In addition, workers should take appropriate safety measures, such as wearing protective gear, to avoid injuries.